Less is more for copper catalyst when it comes to synthesising acetate from CO

Electrochemical process that targets specific intermediate produces valuable chemical feedstock more efficiently

A far more efficient and selective catalyst for electrochemically reducing carbon monoxide to acetate has been developed by an international collaboration headed by researchers in China and Canada. They found that less is more when it comes to the copper catalyst, and that reducing the amount used actually inhibits side reactions, producing more acetate.

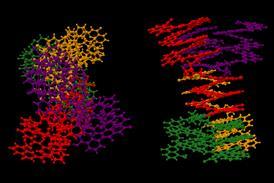

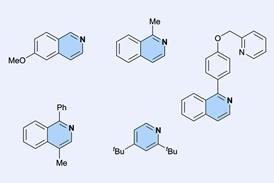

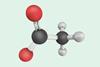

More than 18 million tonnes – worth nearly £8 billion – of acetic acid are produced every year as solvents and precursors to other chemicals used in paints, adhesives, food additives and other applications. The standard synthesis starts with syngas and generates 1.6kg of carbon dioxide-equivalent emissions per kilogram of acetic acid produced. Acetate can instead be produced electrochemically from carbon dioxide or carbon monoxide using copper-based catalysts. ‘If you look at the metals in the periodic table, copper is the only metal that balances the adsorption strengths of the intermediates that we care about to facilitate carbon-carbon coupling,’ explains Joshua Wicks a of the University of Toronto in Canada. The acetate is just one chemical in a mixture of ethylene, ethanol, 1-propanol and others.