The complex chemistry of making paper

Renewable, recyclable and biodegradable, paper is the ultimate sustainable material. Victoria Atkinson looks at the clever chemistry that turns trees into sheets

Paper is a ubiquitous material in modern life, so commonplace we often overlook it altogether. It appears in almost everything that we do, from our work to our food and even our health.

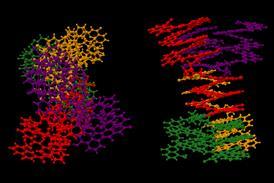

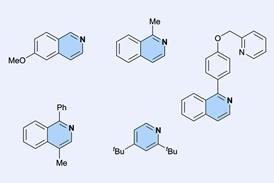

At a chemical level, paper is made of cellulose fibres pressed and bound together by hydrogen bonds, but it’s the crucial pulping step that accounts for paper’s unusual strength. As the wood is beaten into a pulp, the individual cellulose fibres separate and form a suspension within the water. A complex network of hydrogen bonds then forms between these chains as the water slowly evaporates, creating a tightly crosslinked sheet of fibres. This seemingly simple structure is underpinned by a raft of complex chemistry, however: details such as the source of cellulose, how the fibres are handled and the chemical treatments incorporated into the manufacturing process can radically alter the properties of the finished paper. This incredible tunability is what makes paper such a versatile material and mills carefully control every parameter to create the perfect product.