Used masks and plastic packaging turned into high-octane fuel at low temperatures

Endothermic reaction coupled with an exothermic one to keep the processes energy costs down

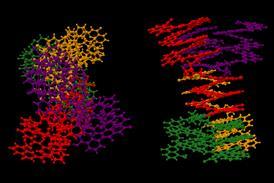

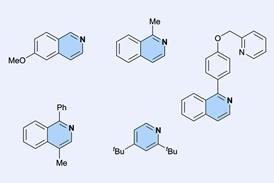

A new process can convert waste polyolefins into high-value liquid iso-alkenes at temperatures below 100°C. The method couples the endothermic breakage of the carbon–carbon polymer chain with the exothermic branching reaction, meaning little heat is needed to break down the polymer. What’s more the researchers were able to convert almost all of a variety of common consumer waste products into these valuable hydrocarbons.1

Owing to the difficulties of recycling polymers by traditional, mechanical means, attention is increasingly turning to innovative ways of chemically converting waste plastic into either new plastic or more valuable materials. Conversion of polyolefins, such as polyethylene and polypropylene, however, is particularly challenging, as the carbon–carbon bond is extremely stable, so breaking it usually takes a lot of energy. Researchers have tried to circumvent this by coupling the endothermic reaction to another exothermic reaction to produce processes that will run at low temperatures. However, the activation barriers usually mean that these require temperatures of over 200°C to run at an appreciable rate.