Waste plastics unzipped into useful pieces

Chemical recycling of polyethylene produces feedstock usually obtained from crude oil.

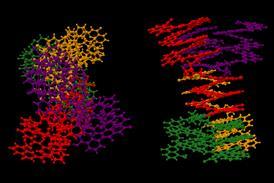

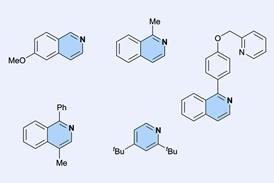

A new catalytic system has been developed that can unravel plastic polymer chains into small chemical fragments. These chemicals are usually obtained by industry from crude oil and this depolymerisation technology can turn used plastics into propylene to make new plastics.

Polyethylene is cheap and strong making it ideal for packaging and single use products across the world – this also means it is the largest contributor to global plastic waste. Current recycling practices generally depend on mechanical processes which degrade the quality of the plastic and therefore limit the use of the recycled material. The inert hydrocarbon chains make these materials particularly resistant to chemical degradation and, although modification can produce upcycled plastics with new properties, the demand for these products is too low to make this a viable recycling strategy. In addition, most plastics are produced from petrochemicals extracted from crude oil, meaning mechanisms to recover these chemical feedstocks are highly desirable.