Synthetic polymer materials are one of the most important inventions of modern times. Thanks to their superlative properties they are now ubiquitous, and an integral part of our lives. Yet they also have a significant environmental impact, and governments, businesses and individuals alike all recognise there is an urgent need to address how we make and use polymers.

Policy programmes such as the EU’s circular economy action plan, for example, are already driving the transition from the make–use–dispose paradigm towards circularity: making better use of our resources and preventing valuable materials from becoming waste and pollutants. In this collection, our partners discuss how they are enabling that change.

Recycling is one of the key ways to ensure that polymers do not enter waste streams, so increasing recycling rates and the use of recycled materials is a priority for many governments around the world. This presents a challenge for the polymer industry and its customers, however, because recycled materials can have very different properties to virgin resins. Ensuring that recycled products perform to the same standards and meet the same regulatory requirements means having a detailed understanding of the materials and how to process them. Our partners at Waters Corporation have a deep understanding of these challenges and extensive experience in using analytical chemistry tools to characterise materials and improve processes such as plastics recycling.

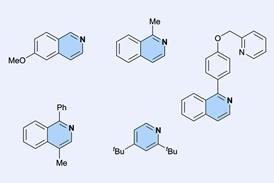

In the longer term, innovations such as chemical recycling, using bio-based feedstocks and new more sustainable plastics are expected to improve our stewardship of materials and reduce our dependence on fossil fuels. Yet new materials face significant barriers to reaching the market and long development times. Our partners at Schrödinger specialise in using modelling to shortcut development timescales so that products can get to market faster. Computational modelling can support every stage of the process, from design through to processing and assessing a material’s performance, or making existing products more sustainable. All of which can vastly reduce the time and resources needed compared to conventional methods.

Polymers have transformed the way we live. Putting sustainability at the heart of how we use them will ensure that society can continue to benefit from these valuable materials.

Welcome to the sustainable polymers collection

- 1

Currently reading

Currently readingWelcome to the sustainable polymers collection

- 2

- 3

- 4

- 5

No comments yet