Catalyst-free strategy allows Raft polymers to be unzipped for recycling

The approach exploits active end groups produced during the polymerisation process to regenerate the starting monomers in excellent yield

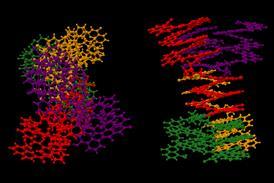

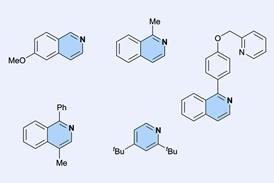

A simple way to reverse a popular controlled radical polymerisation method has been developed by making use of specific end groups produced during the process. The new approach allowed the researchers to regenerate the starting monomers from linear and bulky polymers, reaching conversions of up to 92% without requiring a catalyst.

Controlled radical polymerisation techniques can be used to make polymers with narrow molar mass distributions and well-defined structures, but their high costs have limited the commercialisation of these materials. ‘We believe we have taken a significant step towards bypassing this hurdle,’ says Athina Anastasaki from ETH Zurich. ‘Our approach takes advantage of the very active end groups installed by reversible addition-fragmentation chain-transfer (Raft) polymerisation.’