Timmers’ towers and Straus’ flasks

The revolutionary system that made labs much less likely to go up in flames

What do you fear most in the lab? Although I have lit more hydrogen balloons, white phosphorus and magnesium/perchlorate fuses than most, just the idea of a fire in a lab fills me with limbic dread. But fires have been a grim reality for chemists since the subject was born. Much of synthesis is done in liquid fuel, often at the boiling temperature. To compound it, our solvents need to be anhydrous. Traditionally this meant a row of solvent stills which in the ‘good old days’ sat in a row on a spare bench: two litres of solvent, alkali metal or metal hydride, all topped off by a water condenser. What, in that hackneyed phrase, could possibly go wrong?

But the stills were only the beginning. The sodium press in the corner of the lab was used to extrude a few meters of slender metal thread into the Winchesters stored in cupboards under the bench. And then there was disposal of old still-pots, gently feeding alcohol, hour by hour, into a brown glop spiced with silvery nuggets of eruptive metal… it still gives me the shivers.

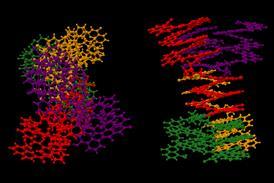

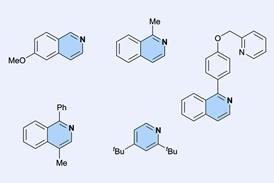

That we no longer have this to worry about can be traced to an industrial research lab in the US. In the 1980s a new class of polymerisation catalysts emerged based on a metallocene framework. These constrained-geometry ‘living’ catalysts were not just highly active, but they also gave narrow molecular weight distributions that gave them more tunable properties. At Dow Chemical’s central research station in Midland, Michigan, the chemist James Stevens set up a team of scientists to investigate them further. Among these was Francis ‘Frank’ Timmers, who’d spent five years as an academic at a small college in his home state of Wisconsin. Unlike the rest of Dow’s huge polymer production, the systems that Stevens and his team developed operated in hydrocarbon solutions rather than with gases or slurries. The extreme Lewis acidity of the hundreds of catalyst candidates that they prepared and screened required meticulous attention to moisture. There was therefore a set of stills in the lab whose presence made the group quite nervous.

It occurred to Timmers and his colleague Rob Rosen that solvents were never dried by distillation on a production scale, but with drying agents like alumina or molecular sieves. They therefore set up the equivalent of a chromatography column packed with alumina in their glove box, poured commercial grade solvent through it, and tested their catalysts. Sure enough, the solvent was as dry as a bone.