Electrochemistry on an industrial scale

Sizzling temperatures and millions of tons

If you’re a curious child, there’s something fascinating about turning a light on and off and trying to figure out how it works. My electrical engineer father gave me loads of books about electricity, and from there, I learned of Humphry Davy and Michael Faraday’s exploits with large voltaic piles of zinc and copper. In their laboratory at the Royal Institution, the voltaic piles provided the power for carbon arc lighting, one of the first examples of using electricity to do useful work. Davy also used the piles to isolate a number of elements, including potassium from potassium hydroxide. This demonstrated a key aspect of electricity and electrochemistry: producing useful chemical products.

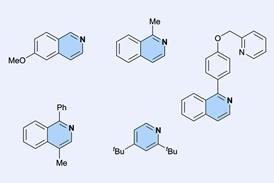

Fast forward two hundred years, and there are endless examples of electricity powering our world and helping us get work done. Our laboratories are lit by electric lights and electric motors help us keep our reactions stirring. Electricity also helps us make chemicals directly as well. Organic electrochemistry has had something of a renaissance in recent years, with Professor Phil Baran of Scripps Research Institute’s efforts to popularise and standardise synthetic organic electrochemistry via the IKA Electrosyn apparatus. This unit offers the curious laboratory chemist the basics of electrochemistry, where the reaction mixture can be placed in a small vial and cyclic voltammetry experiments can be run with various standardised electrodes.

Organic electrochemistry isn’t just done at 10ml scale, either. It’s done on pilot plant and commercial plant scale by chemical manufacturers like BASF. Many examples are as you would expect: benzylic oxidations to produce aromatic aldehydes, for example.